Enhancing Business Efficiency with Industrial Blower Products

In today's rapidly evolving industrial landscape, companies face the constant challenge of improving operational efficiency while maintaining quality standards. One of the often-overlooked tools in achieving this is industrial blower products. These machines, designed to move air and gases, play a crucial role across various industries. From manufacturing to construction, their applications are broad, making them indispensable in many operational processes.

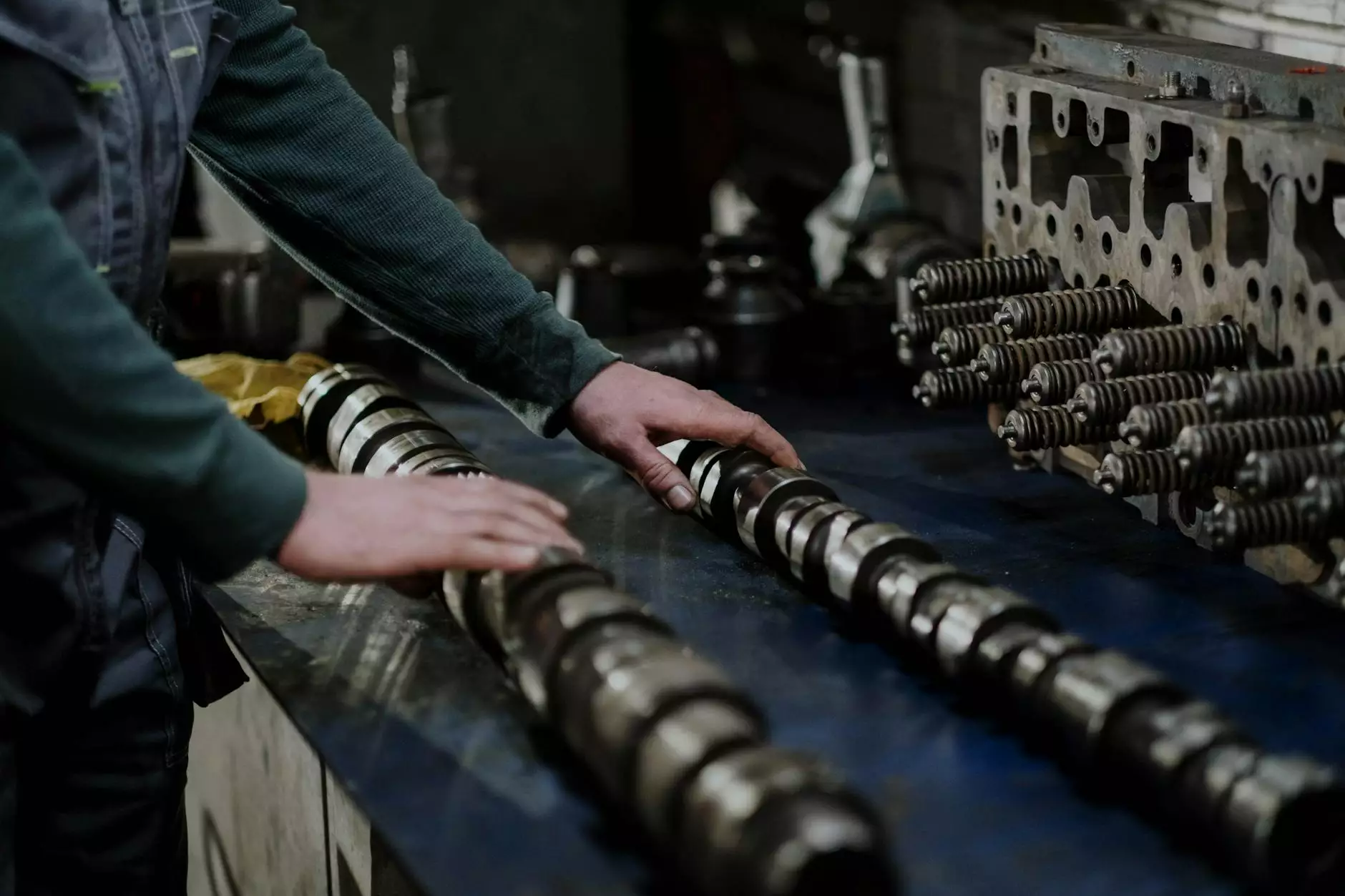

Understanding Industrial Blower Products

Industrial blower products are powerful devices used to generate high-volume airflow. They serve multiple functions, including cooling, venting, drying, and conveying materials. By moving large quantities of air, these blowers help maintain optimal conditions and enhance productivity in several settings.

The Types of Industrial Blowers

There are several types of industrial blowers available in the market, each designed to meet specific requirements:

- Centrifugal Blowers: Utilizing a rotating impeller, these blowers increase the velocity of air and then direct it outwards. They are widely used for ventilation and drying processes.

- Positive Displacement Blowers: Known for their ability to move a consistent volume of air, these blowers are often used in applications requiring high pressure.

- Axial Blowers: These blowers use a propeller to move air axially and are perfect for ventilation tasks where high volume and low pressure are needed.

Key Advantages of Industrial Blower Products

Investing in industrial blower products can yield numerous benefits that significantly enhance business operations:

1. Increased Efficiency

Industrial blowers facilitate faster drying, better ventilation, and effective cooling, which collectively lead to enhanced efficiency in production lines.

2. Cost-Effectiveness

By streamlining processes and reducing operational downtime, businesses can see a significant reduction in costs associated with production inefficiencies.

3. Improved Air Quality

Many industries, especially manufacturing and construction, can benefit from improved air circulation, reducing harmful particulates in the working environment to promote a healthier workforce.

4. Versatility

Industrial blowers can be tailored to meet specific industry needs, whether in large-scale manufacturing or smaller-scale applications such as woodworking shops or food processing facilities.

5. Enhanced Safety

Proper ventilation created by industrial blowers can reduce the risks associated with flammable or toxic fumes, ensuring a safer work environment for employees.

Applications of Industrial Blow Products

Understanding where and how industrial blower products can be applied is crucial for any business. Below are some common applications:

1. Manufacturing Facilities

In manufacturing plants, blowers are often used for cooling equipment, removing dust, and maintaining comfortable working temperatures. This is particularly important in industries like electronics, where overheating can lead to significant malfunctions.

2. Wastewater Treatment

In wastewater treatment facilities, blowers provide the necessary aeration for the biological processes that break down waste materials. They facilitate improved oxygen transfer, which is essential for effective sewage treatment.

3. Food and Beverage Industry

Blowers play a pivotal role in the food sector, from drying fruits and vegetables to facilitating the cooling of processed products. Ensuring a clean and dry environment is vital for maintaining food safety standards.

4. Construction Sites

During construction, blowers are used for dust control, ventilation of confined spaces, and drying of materials. They ensure that construction sites are safe and comply with regulations regarding air quality.

5. Agricultural Applications

In agriculture, blowers are used for tasks such as drying crops post-harvest, ensuring proper air circulation in storage facilities, and maintaining optimal conditions in greenhouses.

Choosing the Right Industrial Blower

Selecting the right blower depends on several factors:

- Flow Rate: Determine the required airflow for your specific application. This is often measured in cubic feet per minute (CFM).

- Pressure: Identify the pressure requirements needed for your process. Different applications may require either low or high-pressure blowers.

- Energy Efficiency: Consider blowers that offer energy-efficient models to reduce operational costs over time.

- Build Quality: Ensure the blower is made from high-quality materials that can withstand various conditions and heavy use.

- Noise Level: Evaluate the noise output, especially if the installation is in a sensitive or populated environment.

Integrating Industrial Blower Products with Blow Dry/Out Services

tmm.com.tr offers comprehensive blow dry/out services that can greatly benefit from the integration of industrial blower products. Not only do these blowers facilitate quicker drying times, but they also optimize energy use during operations.

Advantages of Combination Services

By combining industrial blowers with professional blow dry/out services, businesses can:

- Reduce Downtime: Faster drying processes lead to quicker turnaround times for projects.

- Standardize Quality: Consistent application of drying processes enhances quality across the board.

- Adapt Quickly: Industrial blowers can be adjusted to meet varying production demands effectively.

Maintenance and Care of Industrial Blower Products

To ensure longevity and peak performance from industrial blower products, regular maintenance is paramount. Here are some fundamental practices:

1. Regular Inspections

Conduct routine inspections for wear and tear and address any issues immediately to prevent larger breakdowns.

2. Cleaning

Dust and debris can severely affect blower performance. Schedule regular cleaning to ensure optimal airflow and efficiency.

3. Lubrication

Keep moving parts adequately lubricated to reduce friction and wear, which can lead to equipment failure.

4. Check Electrical Components

Inspect electrical components for any signs of corrosion or damage, ensuring that the power supply is stable.

5. Professional Servicing

Consider hiring professionals for periodic servicing of blowers, as they can spot and resolve issues that may not be immediately apparent.

Final Thoughts on Industrial Blower Products

In conclusion, the significance of industrial blower products in driving business success cannot be overstated. From improving efficiency to enhancing workplace safety, these powerful machines serve multiple functions that can substantially boost operational performance. By integrating these blowers with high-quality blow dry/out services provided by tmm.com.tr, businesses can achieve remarkable enhancements in their processes, leading to improved profitability and sustainability.

As industries continue to evolve, the demand for sophisticated solutions like industrial blowers will grow. By staying ahead of the curve and investing in these technologies, businesses can secure their place at the forefront of their respective markets.